Corpuscle

CNIT manufacturing

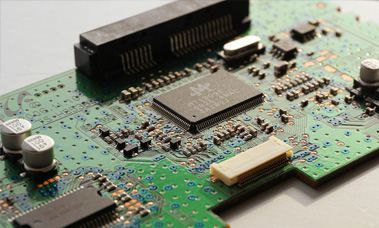

CNIT manufacturing base covers a total area of more than 90,000 square meters, It has 12 new FUJI patch lines, 3 global patch lines, 8 new wave soldering and plug-in repair welding lines, 2 selective wave soldering and plug-in repair welding lines, and more than 20 professional test equipment such as XRay, 3070 ICT, Tyradye ICT, 3D AOI, BSI, TR5001 MDA. Yunjian Information is equipped with the world's mainstream production auxiliary equipment, assembled more than 20 years of production experience of the engineer team, adhering to the high standard of process management and quality system, to provide customers with high-quality manufacturing services.

Manufacturing service scope

CNIT supply chain has a complete manufacturing system, can provide customers with a full range of EMS manufacturing services, including board, server, network machine and other products trial production, mass production services.

CNIT Supply Chain Advantages

Supply chain systems and architectures that meet customer product quality requirements, operate efficiently and cost competitively

① Maintain transparent information interaction and communication with customers, and quickly respond to customer needs

② ICT product device platform and quality control and production delivery capabilities covering different customer needs

Fast new product trial production, verification, introduction and process quality assurance ability

① High-end, complex large size PCBA trial production, verification and mass production capacity

② End-to-end quality data traceability and quality problem warning and rapid response capability

The ability to adapt to customer needs and provide delivery models that match them

① Flexible material supply and multi-mode production organization and manufacturing capability

② Ability to cooperate with customers to establish end-to-end supply coordination guarantee mechanism

CNIT Intelligent Manufacturing Culture

Customer-oriented, rapid response, excellent quality, open cooperation, professionalism is

CNIT 's unique Supply chain management culture

CNIT Intelligent Manufacturing Capability

CNIT has established a supply chain system that can quickly respond to customer needs, and has product device platforms and quality control and production and delivery capabilities to support different customer needs.

Can efficiently provide customers with manufacturing services that meet quality needs and have cost competitiveness.

| Project | Manufacturing capability | |

|---|---|---|

| PCB size | / | Length 50 ~ 1000mm Width 50~600mm Thickness 0.508 ~ 6.0mm |

| PCBA weight | SMT | ≤ 6kg |

| Patch | Weight | Device weight/adsorbable area≤ 0.288 g/was |

| Maximum weight of the device ≤ 255g | ||

| Size | Minimum size: 01005 | |

| Size range of machined components: 0.25* 0.125mm ² --102*102 mm² | ||

| Special Insert machine | Maximum cartridge pressure (N) : 98N | |

| Plug-in devices: VGA port, USB socket, pins, various special-shaped parts, DIMMs, switch buttons, high-speed communication ports, network port connectors, PCIE sockets, etc. | ||

| Maximum plug-in device size: 145mm*26mm*45mm (L*W*H) | ||

| Plug-in accuracy tolerance: ± 0.02 mm | ||

| Packaging requirements | Packaging: belt type, disk type, tube type | |

| Maximum type of material that can be placed in the wire body | Tape type ≤ 540 8mm FEEDER | |

| Tray feeder number | Disk type ≤ 48 | |

| Mounting accuracy | Equipment accuracy ± 22μ m (3σ) , ± 0.05 & deg; (3σ) | |

| Machinable components | Maximum height: 25.4mm | |

| Plugins | Transport rail inclination | 4--7° |

| Temperature accuracy | ± 3℃ | |

| Pin spacing | Pin PITCH (PITCH)≥ 1.78 mm (Pad edge spacing ≥ 0.5mm) | |

| Welding protection | Nitrogen protection | |

| Crimping | Peak stabilization accuracy | ± 0.15 mm |

| Down height accuracy | ± 0.02 mm < / td > | |

| Pressure range | 0-50KN | |

| Pressure accuracy | Standard value ± 2% | |

| Control mode | Servo crimping, force and stroke control | |

| Test | Board function | ICT (can support 7680 test points) MDA (1280 test points supported). BSI (customized test items and parameters according to customer needs) |

| FBT (customized test items and parameters according to customer requirements) | ||

Cooperative Consultation

Factory address

Administrative headquarters and R&D address in Hangzhou

Contact person and phone number

Mailbox

No. 19 Hardware Road, Xiaoshan District, Hangzhou

No.39 Jincheng Road, Xiaoshan District, Hangzhou

Mr. Liu 17280721739?

.png)

0571-82835676

0571-82835676

CH

CH